FAULT/EVENT RECORDING PANEL

Product Overview

A power system composes of various electric facilities such as electric power generator, switch gear, circuit breaker, transmission line, distribution line, and electric load. It is distributed through wide spread area and its characteristics changes in real-time basis depending on operating and load condition.

Considering an effect of power system’s fault to the industry and maintenance period, through its prompt restoration and recurrence prevention through an analysis of a cause should be important. Also during a system operation, such solution is needed to prevent any system fault through analysis of electric signal status

Thus in a power system industry, system monitoring, analysis and fault preventions are getting more attention. Through acquiring data about which operational state of each power system facility and protection/ control system, a data analysis and prevention will be implemented.

A fault recording panel is used for analysis of trouble’s cause and operation status of system. When a power system has an abnormal condition (fault, power swing, disturbance, etc), it utilizes by recording and analyzing not only activation status of system’ s protection and control device, but also electric data (voltage, current, frequency, active/reactive power, power factor, etc).

GABO’s fault recording panel has a digital fault recorder (SIMEAS-R) made from SIEMENS, in order to guarantee a reliability. By having accumulated knowledge in manufacturer technology of protection panel, and experienced professionals, we strive to accomplish noise immunity, stable earthing, durability, insulation, assembly, all of which being incorporated in order to generate products of credibility.

FAULT/EVENT RECORDING SYSTEM CONFIGURATION

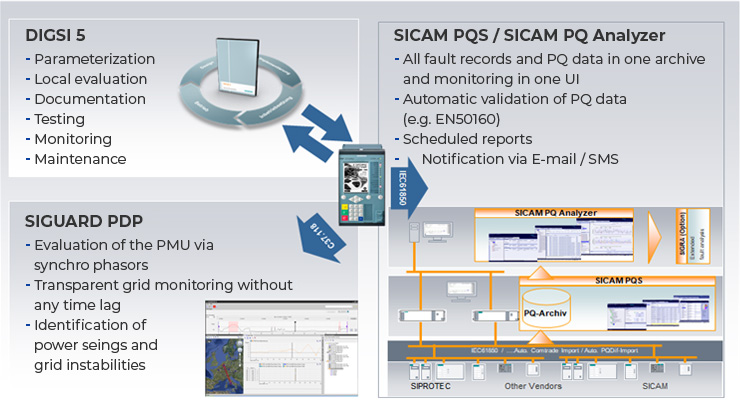

Fault recording system is composed of 7KE85 (fault recording device), software (SICAM PQS, SICAM PQ Analyzer) for monitoring and operating, a printer, and an industrial computer for a system operation.

Depending on user’s purpose, a system configuration could be applied in various ways. Communication network for remote monitoring supports serial, Modem and TCP/IP.

Also, time synchronization could be done by using GPS signal. Time synchronization function of each device enhances an accuracy of analyzing a cause of fault/event.

FAULT/EVENT RECORDER (7KE85)

-

- Digital Fault Recorder with 32 Bit microprocessor

- GPS time synchronization

- Analog (voltage, current, frequency, etc.) high and low limit change and change rate accident data recording function

- 1kHz to 16kHz[Sample]/1[cycle] sampling frequency selectable

- GOOSE signal recording possible

- Ethernet LAN (TCP/IP)

- Signal adjustment function for binary input(On->OFF, OFF->ON)

- External mass storage (Siemens SDHC memory card only) with 16 GB

- LED setting function for each element upon user request

FAULT/EVENT RECORDER MAIN FUNCTION

- A synchronizing storage recorder for 40 analog inputs and 64 digital inputs

- Auto operation mode/ manual operation mode

- Event data recording trigger setting through scheduler/ event setting

- Remote control and setting by using DIGSI 5 at Local PC

- Calculation of power quality through using SICARO-PQ software

- Phasor Measurement Unit (PMU) function and IEC 61850 support

- Fault point display function and Comtrade conversion. (1999/2013 IEEE Standard selectable)

TECHNICAL SPECIFICATION/STANDARD

| Category | Item | Specification | |

|---|---|---|---|

| Rating | Power Supply | Voltage Input | DC : 48~300[V], AC : 80~265[V] (Frequency 50/60[hz]) |

| Power Consumption | Modular Type : Basemodule standard DC 13[W], AC 55[VA]/ Per expansion module : DC 3W, AC 6VA | ||

| Analog | Current(CT) | 1[A] or 5[A], Responsibility : Approx. 0.1[VA] | |

| Power(PT) | 0~200[V], Power Consumption < 0.1[VA] | ||

| Digital Input |

Number of Contacts : Selectable via multiple expansion modules Voltage Range: 24 to 300[VDC] |

||

| Digital Output |

Number of Contacts : Selectable via multiple expansion modules Allowable Current: 5[A](Continuous), 30A for 1s, 250A for 30ms |

||

| Communication | Port | RS-232, RS-485, Ethernet, FO(Fiber Optic) | |

| Protocol | Profibus, DNP3.0, IEC61850, TCP/IP | ||

| Time Synchronization | DCF77/IRIG-B/SNTP/IEEE 1588 | ||