ELECTRICAL EQUIPMENT CONTROL & MONITORING SYSTEM [ECMS]

System Overview

For some years now, power generation and distribution have been undergoing major changes.

The innovation cycles (where operating equipment and communication media are concerned) are getting ever shorter, and the market is becoming increasingly deregulated.

SICAM PAS (Power Automation System) meets all the demands placed on a distributed substation control system - both now and in the future. Amongst many other standardized communication protocols, SICAM PAS particularly supports the IEC 61850 standard for communication between substations and IEDs. SICAM PAS is an open system and - in addition to standardized data transfer processes - it features user interfaces for the integration of system-specific tasks and offers multiple automation options.

Providing an innovative solution such as various tasks to a distributed information system, our ECMS is an adequate system for fields of manufacturing fields, power plants, and substations. Designed as an open system compatible with wide-spread used communication standards, SICAM PAS product is modular. As elaborate Human-Machine Interface (HMI) development software, SICAM PAS CC provides many options for various system maintenance and management with various operation options.

Through Simple Network Management Protocol (SNMP), rapid fault detection and a credibility of operation are provided, plus DNP 3.0 and other different communication regulations. And it applies to power plants and control monitoring systems of substation, so as to provide an economical solution that enhances efficiency of each electrical power facilities.

SYSTEM OVERVIEW, APPLICATION AND FUNCTIONALITY OF SICAM PAS

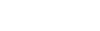

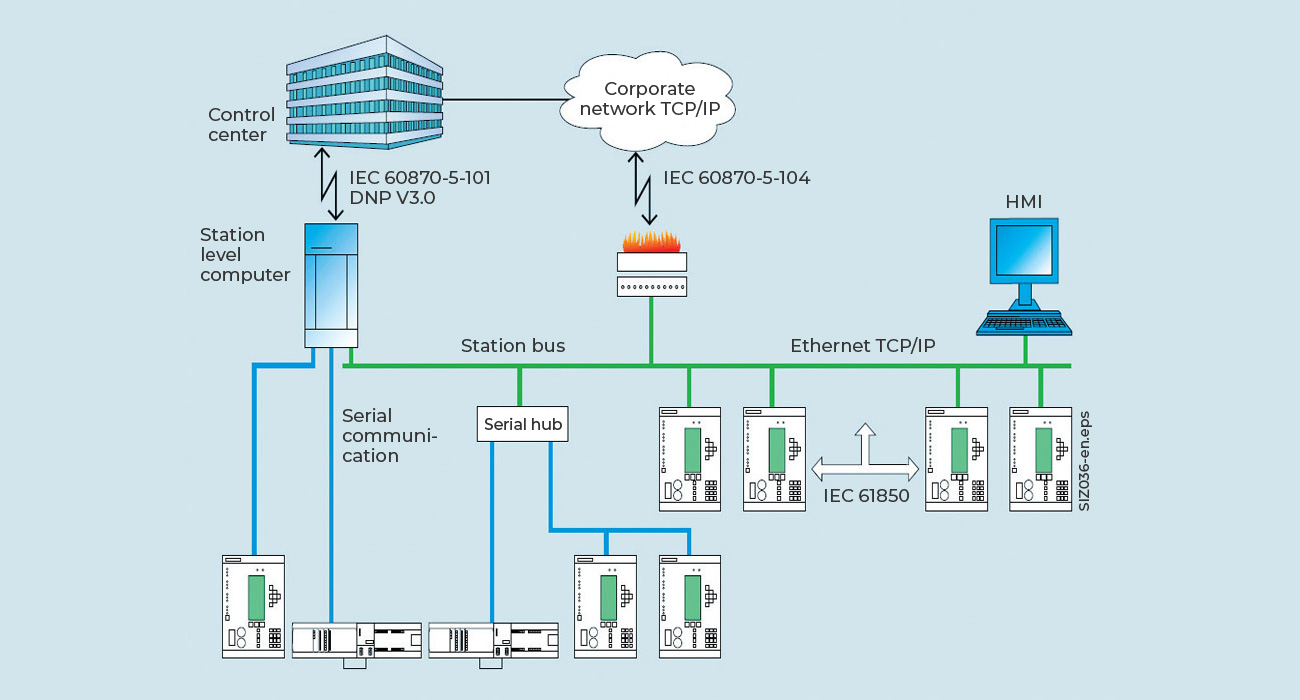

SYSTEM ARCHITECTURE

SICAM PAS works on industrial-standard hardware with the Microsoft Windows operating systems. The advantages of this platform are low hardware and software costs, ease of operation, scalability, flexibility and constantly available support. With the powerful real-time data distribution system, applications can be allocated among several computers, thus boosting performance, connectivity and availability.

A database system stores and organizes the data basis (e.g. configuration data, administrative status data, etc). The device master function for communication with Intelligent Electronic Devices (IEDs) supports a large number of well established protocols.

The SICAM PAS data normalization function allows conversions such as measured-value filtering, threshold value calculation and linear characteristics.

SICAM PAS CC is used for process visualization. Specifically designed for energy applications, it assists the operating personnel in optimizing the operations management.

It provides a quick introduction to the subject matter and a clearly arranged display of the system’s operating states. SICAM PAS CC is based on SIMATIC WinCC, one of the leading process visualization processes that is used in industrial automation worldwide.

To facilitate incident analysis, the fault recordings from protection units are retrieved and archived automatically during operation. This is particularly supported for the standard protocols IEC 61850 and IEC 60870-5-103, but also for PROFIBUS FMS (SIPROTEC 4).

Fault recordings are visualized and evaluated with the program Comrade View as standard. Alternatively, SIGRA 4 with its additional functions can also be used.

COMMUNICATION

DEVICE INTERFACES AND COMMUNICATION PROTOCOLS

In a substation which configure and operate with SICAM PAS, various types of protection units, IEDs, bay control units, measuredvalue recorders and telecontrol units from a wide range of manufacturers can be used. SICAM PAS offers a large number of commercially available communication protocols for recording data from various devices and through differing communication channels.

Available Protocols

| IEC 61850 | IEC 61850 is the communication standard for interconnecting the devices at the bay and station control levels on the basis of Ethernet. IEC 61850 supports the direct exchange of data between IEDs, thus enabling switching interlocks across bays independently of the station control unit, for example. |

|---|---|

| PROFIBUS FMS | Most SIPROTEC 4 bay controllers and protection units can be connected to the SICAM PAS station unit via PROFIBUS FMS. |

| IEC 60870-103 | Protection units, IEDs, bay control units, measured-value recorders and transformer controllers from many manufacturers support the IEC 60870-5-103 protocol can therefore be connected directly to SICAM PAS. |

| IEC 60870-5-101(MASTER) |

The IEC 60870-5-101 protocol is generally used to connect telecontrol units. The ‘balanced’and ‘unbalanced’traffic modes are supported. Automatic dialing is also supported for the connection of substations with this protocol. SICAM PAS can establish the dial-up connection to the substation either cyclically or as required (e.g. for command output). |

| IEC 60870-5-104(MASTER) | Furthermore, connection of substations is also suppor ted by the TCP/IP-based IEC 60870-5-104 protocol. |

| PROFIBUS DP | PROFIBUS DP is a highly powerful field bus protocol. For example, it is used for industrial automation and for automating the supply of electricity and gas. PROFIBUS DP serves to interface multifunctional measuring instruments such as SIMEAS P (I, V, P, Q, p.f). |

| ILSA PROTOCOL | - |

| MODBUS MASTER | - |

| DNP 3.0 | - |

SYSTEM CONTROL CENTER CONNECTIONS, DISTRIBUTED PROCESS CONNECTION AND PROCESS VISUALIZATION

FURTHER STATION CONTROL ASPECTS

During e.g. maintenance work or for other operational reasons, information exchange with the control centers or the substation itself can be blocked with the telecontrol blocking and bay blocking functions.

The telecontrol blocking function can also be configured for specific channels so as to prevent the transfer of information to one particular control center during operation, while transfer continues with other control centers. The bay blocking and telecontrol blocking functions act both in the signaling and the command directions.

Channel-specific switching authority also makes it possible to distinguish between local control (SICAM PAS CC) and remote control for the switching direction, but also between control center connections. Circuit-breakers can be controlled in synchronized/unsynchronized mode.

AUTOMATION TASKS

Automation tasks can be configured in SICAM PAS with the CFC (Continuous Function Chart), which conforms to IEC 61131. In this editor, tasks are configured graphically by wiring function blocks. SICAM PAS comes with an extensive library of CFC function blocks, developed and system-tested especially for energy automation.

SICAM PAS features comprehensive redundancy functions to boost the availability of the station automation system:

SICAM PAS CC communicates simultaneously with both redundant station control units. A redundant structure is also possible for process visualization with SICAM PAS CC and fault-record archiving with SICAM PQ Analyzer

SCOPE OF INFORMATION

The amount of information to be processed by SICAM PAS is essentially determined by the following factors

- Performance data of the hardware used

- Performance data of the network

- Size of the database (RDBMS)

- With a distributed PAS system using a Full Server and up to 6 DIPs, a maximum of 350 IEDs and 20,000 data points can be supported.

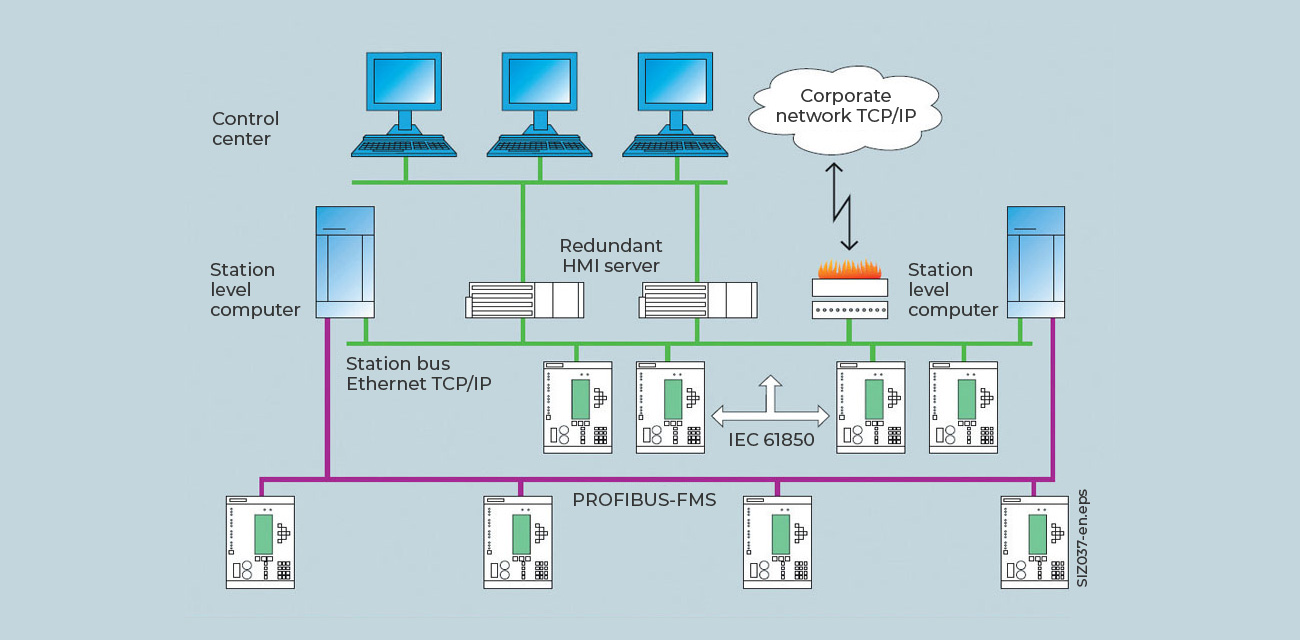

PROCESS VISUALIZATION PROCESS WITH SICAM PAS CC HMI

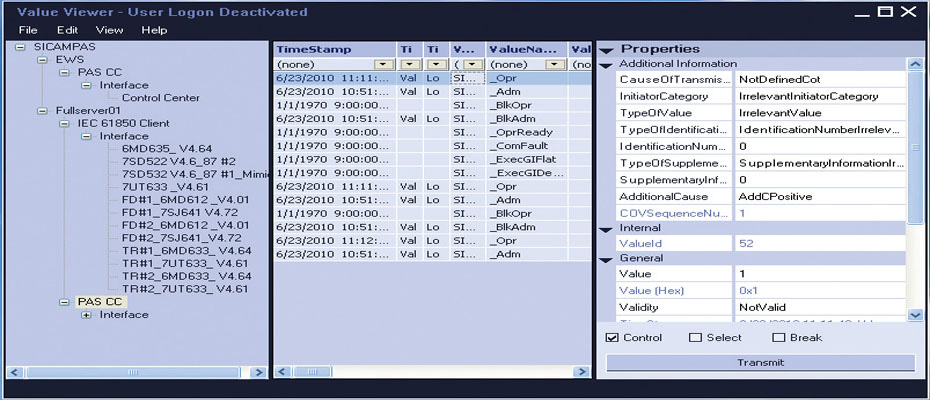

In the operation of a substation, SICAM PAS is used for configuration purposes and as a powerful data concentrator. SICAM PAS CC serves as the process visualization system. In the signal lists, the original time stamps are logged in ms resolution as they occur in the devices. With every signal, a series of additional data is also presented to provide information about causes (spontaneous, command), event sources (close range, local and remote), etc. Besides process signals, command signals are also logged.

IndustrialX-Controls are used to control and monitor the switching devices. These switching device objects support four different forms of presentation (IEC, DIN, SINAUT LSA, SICAM) for circuit-breakers and disconnectors. It is also possible to create bitmaps (defined for a specific project) to represent the switching devices, and to link them to the objects. For informative visualization, not only nominal and spontaneous flashing are supported, but also the display of various device and communication states (e.g. up-todate/ not up-to-date, bay and telecontrol blocking, etc.).

Connected with SCAM PAS units, switching devices are directly or controlled by “SELECT BEFORE OPERATE”mode. Topological Coloring is used for a single line image process, and through internet control and monitoring are implemented. A calculated value analysis by using SICAM VALPRO function, a fault record data collection and saving function in protection relay by using SICAM RECPRO function can be implemented.

SICAM PAS CC is based on SIMATIC WinCC, it has the following impressive features:

- All operation and monitoring functions on-board. These include not only the graphics system for plant displays and the signaling and archiving system for alarms and measured values, but also a reporting and logging system.

- Open standards for easy integration

- Using any external tools, archived data can be accessed through a series of open interfaces (such as SQL and ODBC) for further editing.

- Manufacturer-independent communication with lower-level controllers (or with applications such as MS Excel) is supported with OPC (OLE for Process Control).

- Visual Basic for Applications (VBA), VBScript or ANSI-C creates an ideal scope for project-specific solutions.

- Expandable with options and add-ons such as

WinCC/Dat@Monitor : Serves to display and evaluate current process states and historical data on office PCs, using standard tools such as the Microsoft Internet Explorer or Microsoft Excel

WinCC/Web Navigator : Is an option with SIMATIC WinCC for controlling and monitoring systems over the Internet, a company Intranet or a LAN

WinCC/Connectivity pack : The functions of the two OPC servers HDA and A&E, and of the WinCC OLE-DB provider are ensured by the WinCC/Connectivity Pack.

FunkServerPro : With the aid of the Alarm Management System ACC, messages from the WinCC signaling system can be forwarded automatically to radio call receivers.

OVERVIEW OF OPERATOR CONTROL PHILOSOPHY AND USER INTERFAC

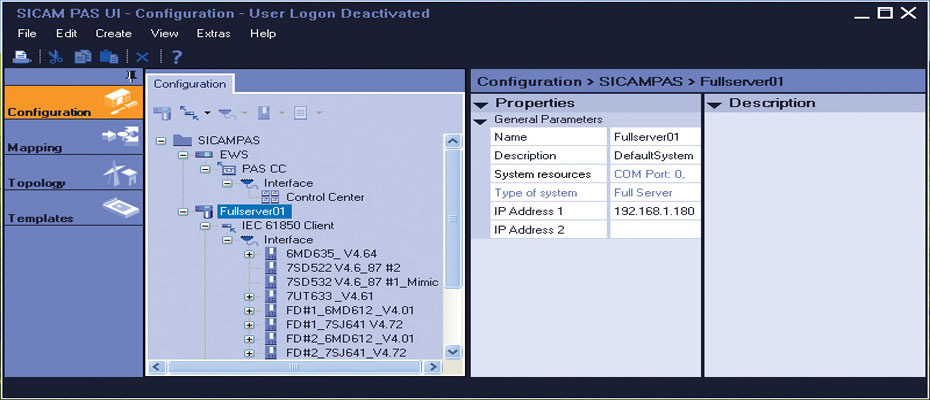

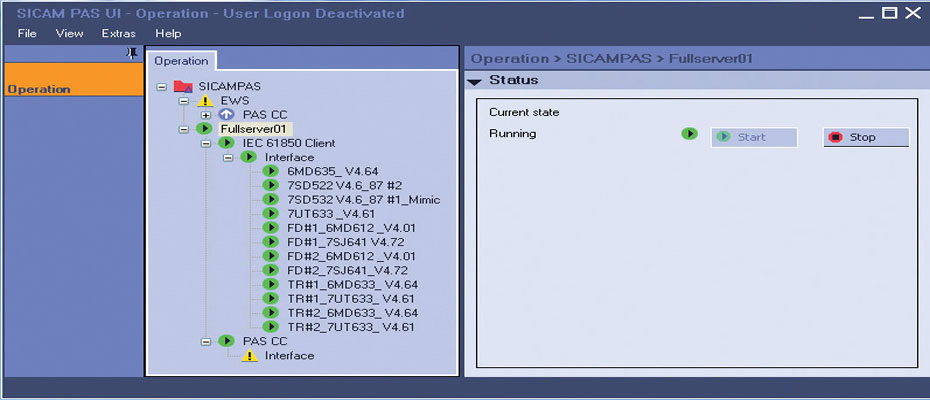

The SICAM PAS user interface is based on customary Windows technology, which enables you to navigate in the familiar Windows environment both when configuring the system and during ongoing operation. The system distinguishes between configuration and operation of a substation. In SICAM PAS, these two tasks are firmly separated by two independent programs.

THE SICAM PAS UI - CONFIGURATION program is used to create and edit a project-specific configuration. To enhance clarity, several views are distinguished

A common feature of all views is that they have an Explorer window that shows the system configuration in a clearly arranged tree structure. As in the Windows Explorer, you can open individual levels of this tree structure to work in them. You work through the necessary steps in the data window on the right. Here, you set parameters, select information and define assignments to a user-specific, process-oriented system topology. The user interface is uncomplicated and structured according to the task definition, so as to enable intuitive working and to simplify changes. The user interface assists the editing process by displaying parameter descriptions and messages when incorrect parameters are entered. In the tabular views for information assignment and allocation to the system topology, configuration is made easy by extensive sorting and filtering mechanisms, multiple choices and Drag &Drop. To ensure data consistency and to avoid redundant data input, SICAM PAS UI provides extensive import and export functions for the exchange of configuration data, e.g. with the bay control level and with process visualization.

SYSTEM REQUIREMENT

| STATION UNIT |

● Processor: - Minimum: Intel Core 2 Duo 1.6 GHz - Recommended: Quad Core CPU 3 GHz ● Primary storage capacity: - Minimum: 2 GB - Recommended for engineering of large stations: ≥ 8 GB ● Hard disk capacity: - Minimum: 4 GB plus configured archive size ● Graphics card: - Minimum: 1024 x 768 pixel - Recommended: 1920 x 1080 pixel |

|---|---|

| SICAM PAS or SICAM PAS CC Operating System |

- Windows 10 Professional/Enterprise/IoT Enterprise LTSC (64-bit) - Windows Server 2019 Standard with Desktop Experience (64-bit) - Windows 7 Professional/Ultimate/Enterprise SP1 (32-bit or 64-bit) - Windows Embedded 7 (SICAM Station Unit V2.40, 32-bit) - Windows 8.1 Professional SP1 (64-bit) - Windows Server 2008 R2 Standard SP1 (64-bit) - Windows Server 2012 R2 Standard (64-bit) - Windows Server 2016 Standard with Desktop Experience (64-bit) |

SICAM PAS UI-CONFIGURATION

SICAM PAS UI-OPERATION

SICAM PAS VALUE VIEWER